Greenwich gets an A for its single steam recycling. The Town’s recycling has a very low contamination rate. As a result, not only does more get recycled, but it also saves the Town money.

Haulers drop tons of single stream recycling at City Carting’s Taylor Reed facility in Stamford. Some towns, including Greenwich, have less contamination, which results in cost savings. Photo: Leslie Yager

The massive green machine custom made by Van Dyk at City Carting’s Taylor Reed facility in Stamford. Photo: Leslie Yager

Jay Greco at City Carting’s Taylor Reed facility in Stamford, where the Town of Greenwich sends its single stream recycling. Photo: Leslie Yager

Greenwich residents are really good about rinsing and sorting metal, glass and plastic containers. Trash is kept apart from recycling, and the ratio of trash-to-recycling continues to improve.

City Carting has 425 employees and 65 are stationed at their recycling plant on Taylor Reed Place in Stamford. It is here that Greenwich’s recycling is sent.

A constant stream of haulers from municipalities, both near and far, back up their trucks to cavernous bays and dump their loads. From there the sorting process begins.

Materials weave their way through a massive $10 million multi-story machine custom made in Germany by Van Dyk for City Carting. The machinery has already been retrofitted twice to keep up with ever tightening requirements from the countries that accept the end product: bales of newsprint, cardboard, aluminum, plastic and rigid plastic.

The machinery purrs and sputters. It whirs and clangs. Much of it is automated, but there are also workers along the conveyor belts who are constant motion, plucking and sorting, sending lighter paper up vacuum chutes and removing plastic bags.

The shifts are long, but there are breaks.

Once or twice a day the entire process comes to a halt for cleaning.

Items are separated in ingenious ways. For example, the machinery sifts out small items like pieces of glass, lids and wine corks.

There are also wind tunnels and magnets, optical beams and sieves.

Like a giant obstacle course, materials make their way through vacuum chutes and over rotating blades.

Items are pulled by magnets and propelled into the air by momentum.

Jay Greco and Andy Tomasello at City Carting’s Taylor Reed facility. The plant houses the massive green Van Dyk machine. Photo: Leslie Yager

During the process, paper is separated from cardboard, and there is tons of it.

“Amazon. Amazon. Amazon,” said City Carting’s Andy Tomasello about the rising quantity of boxes he sees.

He explained that workers train their eyes up the conveyor belts rather than straight ahead to prevent dizziness.

The space that houses the green Van Dyk machine is vast, comparable in size perhaps to the student center at Greenwich High School.

Bales of cardboard at City Carting’s Taylor Reed facility in Stamford. Photo: Leslie Yager

Bales of aluminum at City Carting’s Taylor Reed facility in Stamford. Photo: Leslie Yager

Close up of Greenwich’s single stream recycling, which has low levels of contamination. Photo: Leslie Yager

Jay Greco of City Carting pointed out the striking difference between the quality of Greenwich and other towns’ single stream recycling.

Recycling from Greenwich has a low contamination rate. Plastic bags, food and liquids are visibly absent. Other municipalities sometimes have contamination rates that can rise to 12-15%, and that may cost them.

Single stream recycling from a municipality with more contamination than Greenwich’s. Photo: Leslie Yager

China was until recently an avid purchaser of America’s recycling. But that country has become increasingly picky.

In fact, according to Tomasello and Greco, China even sends spot checkers to Stamford.

At the end of the process, bales of recyclables are stacked, awaiting their destination. Photo: Leslie Yager

“They don’t speak English and our workers don’t speak Chinese, but they communicate,” Greco said. “They come here straight from the ports in New York and break open random bales. They look inside to make sure contamination isn’t hidden.”

“Contamination is a huge challenge in single stream recycling,” Greco said.

Greenwich used to receive a recycling rebate. That is no longer the case.

Up close look at a bale of recyclable plastic at City Carting in Stamford. Photo: Leslie Yager

Greco said that if municipalities continue to have high levels of contamination in their recycling, future processing costs will likely be passed on in the form of a surcharge from local haulers.

“We’re at a real turning point,” Greco said. China’s pickiness has depressed the value of all recycled goods.

Sign up for the free Greenwich Free Press newsletter

Sign up for the free Greenwich Free Press newsletter

Glass products have always cost plants money to recycle, but in the past that was counteracted by the profit generated from selling paper and cardboard.

Greco said about 40% of single stream recycling is newspaper, 20% cardboard, 20% glass, and 20% aluminum.

Conveyor belt at City Carting’s Taylor Reed facility in Stamford. Photo: Leslie Yage

At one point in the process, a roller breaks and separates the large and small pieces of glass and filters them into different streams.

A screw-shaped mechanism pulls the small glass into a “zig-zag machine,” one of the retrofits added to the Van Dyk last year.

The zig-zag blows air inside a chamber, separating the glass from contaminated materials like shredded paper, which gets blown into another area of the plant.

Its addition vastly reduces glass contamination, yet the eventual pile of small glass pieces is mixed with other bits like plastic like bottle caps.

A silo containing small pieces of glass, lids, wine corks and other small bits sifted out during the recycling process. Photo: Leslie Yager

“People should keep lids on the bottles when they recycle. That reduces this waste,” Tomasello said, pointing to the silo containing small pieces of glass, lids, wine corks and other small pieces.

The machinery also separates paper from cardboard, but there are three quality control screens where workers manually remove pieces of plastic or cardboard that the machinery misses. The paper then drops into one of the large bins under the Van Dyk.

Workers along a conveyor belt at City Carting’s recycling operation in Stamford. Photo: Leslie Yager

An optic sorter directs a beam of light onto a belt. It can be set to identify a specific material to be removed.

The aluminum is sorted by an Eddy current. A soft iron core spins in a circle, creating a magnetic force field that repels metals. The aluminum flies over the other items and is deposited in its own bin.

Once all the materials are sorted into their respective bins they go on to be compacted and arranged in bales fastened by wire.

The Van Dyk has a state-of-the-art feature that enables it to compress and create hundreds of bales of paper and cardboard automatically.

At a second area in the plant, workers manually compresses make around 50-60 bales a day.

Lastly, trailers are loaded with bales. They head to the docks in New Jersey where they are destined for countries including China, Indonesia, Vietnam and India.

City Carting’s Michael Ferro, who knows the going prices for bales of recyclables, spends much of his day fielding calls from buyers, and making calls to the ports to connect the bales to receiving countries.

A bale of cardboard is bundled in wire by the Van Dyk machine at City Carting in Stamford. Photo: Leslie Yager

Greco and Tomasello explained that while recycling keeps a municipality’s costs down, it’s also better for the environment. The less trash and the more recycling the better. Recyclable materials like plastic virtually never break down when they wind up in landfills or in the ocean.

Greco often visits elementary schools in the community to educate children about recycling. He believes children are key to the future of robust recycling programs.

A worker pulls a plastic bag from a conveyor belt full of cardboard. Photo: Leslie Yager

Pesky Plastic Bags

Greco and Tomasello applaud Greenwich for its upcoming plastic bag ban. They pointed out that plastic bags should not be included in single stream recycling. They jam up the machinery and workers spend extra time plucking them from conveyor belts.

Once or twice a day the machinery comes to a full stop for a thorough cleaning and workers with giant picks remove the plastic bags caught in the rotating blades.

Also, residents are reminded not to place their single stream recycling inside plastic garbage bags.

The workers don’t have the time to open them and the machinery is not designed to pry them open either.

“Just shake the contents out and reuse the bag,” Greco said.

Inside this chamber, (to the left) plastic bags are caught in the rotating blades. Photo: Leslie Yager

Besides, even clean plastic bags that have the potential to be recycled become dirty during the recycling process.

For now, Tomasello’s advice is for consumers to return their clean plastic bags to the stores where they come from so they can be separately recycled.

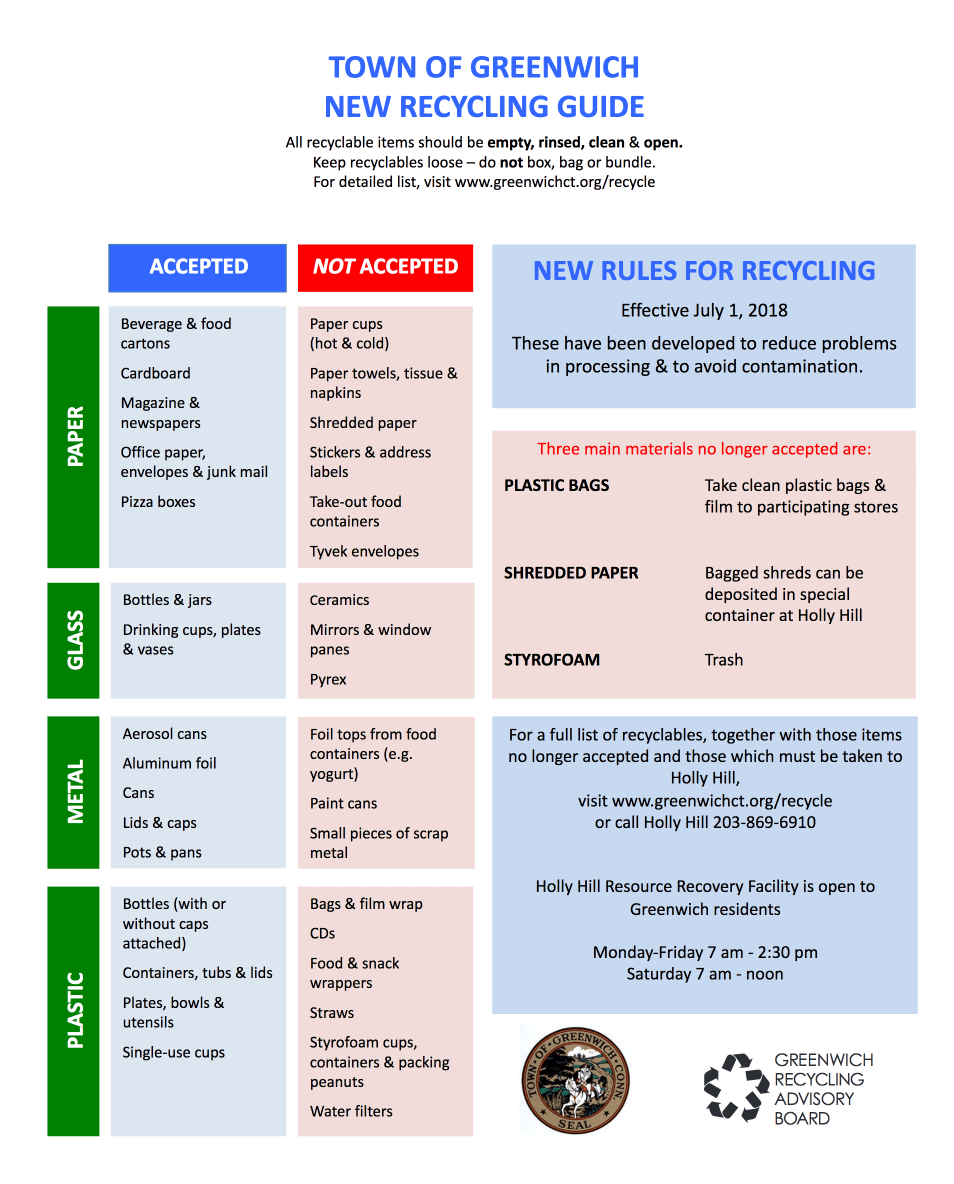

Another fun fact shared by Tomasello is that shredded paper is no longer recycled through the single stream process. Instead, City Carting has provided a bin at Holly Hill for people to deposit their shredded paper.

And those popular meal kits delivered inside bubble wrap bags kept cold by gel packs?

For now, they are not recyclable and are considered trash.

“There’s a lot more that could potentially be recycled, but it just takes a lot of money to do it,” Tomasello said.

At City Carting, rigid plastics are formed into bails. Photo: Leslie Yager

See also:

New Greenwich Recycling Rules: What You Need to Know

Wondering What Happens to Plastic Bags at The Dump? (May 2018)

Sesto Delves into Details of Upcoming Plastic Bag Ban in Greenwich (June 2018)

The Future is Not Plastic in Greenwich. Plastic Bag Ban with Zero Fee Wins in RTM Vote (March 2018)

Trucks are loaded with bales of recyclable material at City Carting’s facility in Stamford. Photo: Leslie Yager

Bales of rigid plastic at City Carting’s facility in Stamford. Photo: Leslie Yager

A bale of aluminum at City Carting’s facility in Stamford. Photo: Leslie Yager